AERO BONNER ENGINEERING HISTORY

| 1968 | Graduate from Cambridge with degree in Mechanical Engineering | |

| 1969 | Start work in Weslake & Co drawing office designing engines | |

| 1971 | Work for BP Australia as engineer in Technical Services Division | |

| 1972 | Return to Weslake to design and build Aero Bonner Sapphire V6 Aero Engine | |

| 1974 | Move to workshop on Shoreham Airport | |

| 1975 | Design single cylinder research engines for Ricardo & Co, also at Shoreham Install Sapphire engine in Chipmunk flying test bed | |

| 1976 | Engine dyno failure: Static exhibitor at Farnborough Air Show. Purchased new block casting from Ford Motor Co. M/C new casting myself on Bridgeport. | |

| 1977 | Commenced overhauling de Havilland Gipsy Major engines. M/C first crankshaft for Ricardo + crankcases & much else + continued to produce engine drawings for them | |

| 1979 | Finished testing & flew Chipmunk powered be Aero Bonner Super Sapphire for first time. Carried out numerous test flights, in accordance with CAA approved test schedule | |

| 1980 | Demonstrated Sapphire flying at Farnborough Air Show. Lots of interest ( RAF, RR ) & advertised in USA, but no cheques. Took on project to turbocharge and marinise the Jaguar 5.3 litre V12 engine to produce 800 bhp. | |

| 1981 | Jaguar bring out May cylinder head & commission Bonner Engineering to develop the combustion chamber to eliminate chronic detonation. SUCCESS. Continue building V12 racing marine engines | |

| 1983 | Ford Motor Co commission Mileage Marathon engine: Design and Manufacture units | |

| 1984 | Intense Development programme of Mileage Marathon engine. Ford achieve World Record of 3804 m.p.g. | |

| 1986 | Start Design of Bonner V6 5.8 ltr Race Engine, and also Africar twin crank engine. | |

| 1987 | Commence manufacture of 6 off Bonner V6 + 1 off Africar engine + Design 12 speed 4wheel drive gearbox for Africar. | |

| 1988 | Run 1st V6 on Dyno + Run Africar on Dyno | |

| 1989 | V6 achieves design spec of 550 bhp on Dyno. Supplied to ADA. V6 Marine Racing Engine achieves 900 bhp, delivery commences to customers. | |

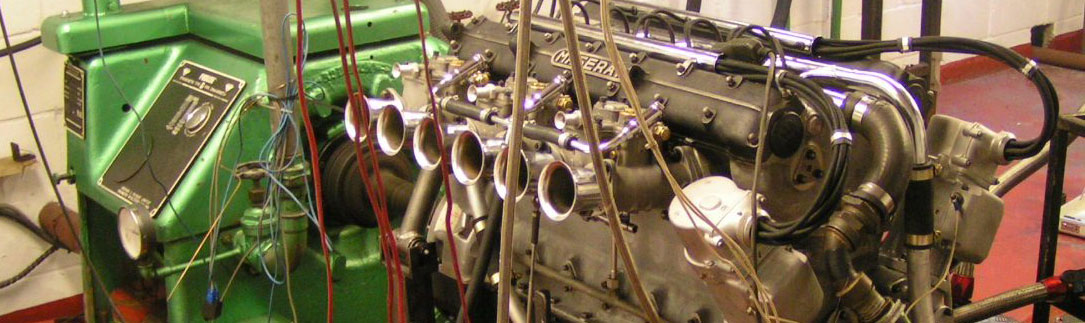

| 1991 | Redesign Maserati 4 cyl race engine & rebuild and test & supply to Steve O’Rourke | |

| 1993 | Overhaul Lycoming TIGO-541 425hp aero engine. Design and build special fan with 145mph exit velocity to cool it on dyno. | |

| 1995 | Re-design Jaguar ‘D’Type engine: New crank and new cam profile raise rpm to 7500 and power output to 350bhp, for Steve O’Rourke. | |

| 1997 | Commence design and construction of Bonner Ballistic Sports Car | |

| 1999 | Chevrolet 9.4 Ltr V8 marine engines rebuild. MG M type engine rebuild. | |

| 2000 | Overhaul Climax 1.5 V8 GP engine ex Lotus24. Redesign defective oil pump and oil system, for Steve O’Rourke. | |

| 2001 | Design and build 8,600 sq ft hangar at Shoreham Airport. Mfr Steel structure; excavate and lay 1000 tons reinforced concrete & erect steel frame, fit cladding, excavate and culvert stream. | |

| 2005 | Redesign Gipsy Major 1 engine to run in erect configuration for use in place of Gipsy 11 to power Gipsy Moth aircraft. Mfr Wet sump, new oil pump and system | |

| 2008 | Mfr Coventry Climax FWA cylinder heads + batch of V8 F1 oil pumps + mod blocks Dyno testing race engines for Jim Stokes Workshops | |

| 2010 | Consultant to Cox Powertrain developing new opposed piston diesel engine Overhauling Renault PO3 engines, c/w redesigned oil pumps | |

| 2012 | Overhaul Coventry Climax FPF engines | |

| 2013 | Consultant to Lugo Engines of Venezuela | |

| 2015 | Consultant to Yan Engines of USA and Brighton | |

| 2016 | Sign contract with Marquette University of Milwaukee, USA for supply of Bonner Hercules single cylinder research engine with variable compression Ratio from 4:1 to 18:1. Commence design and pattern making. | |

| 2018 | Consultant to Weslake Aero with regard to their twin crank aero engine. | |

| 2019 | Complete assembly of de Havilland Bonner Gipsy 11 K engine followed by 18hr endurance dyno test | |

| 2020 | Providing workshop, assembly, machining and dyno test services for OSP Engines in respect of their twin crank experimental stepped piston engine. |