ENGINE DESIGN

We have worked on engine design for such great names as Ricardo, Ford, Jaguar, Weslake, US Government, Chrysler, Lycoming, and less famous Turbeau, Africar plus countless individuals on smaller but nonetheless important projects.

Apart from designing complete engines for the last 45 years, we can offer design work on sub-divisions of an engine.

These break down into:

- Crankcase

- Cylinder Head

- Valve Gear

- Accessories

If asked to design a brand new engine, we would then agree a specification, and then produce a schematic layout incorporating most if not all of the features, together with a feasibility study, setting out a route map which takes the project through to completion, with stages and prices. If our esteemed client is happy with our proposals, we would then proceed from the Scheme to detailed design of the components. Assuming are asked to make a prototype, we would then manufacture the components comprising the complete engine, and then assemble these into the finished engine itself.

Throughout this process we would be in constant communication with our client.

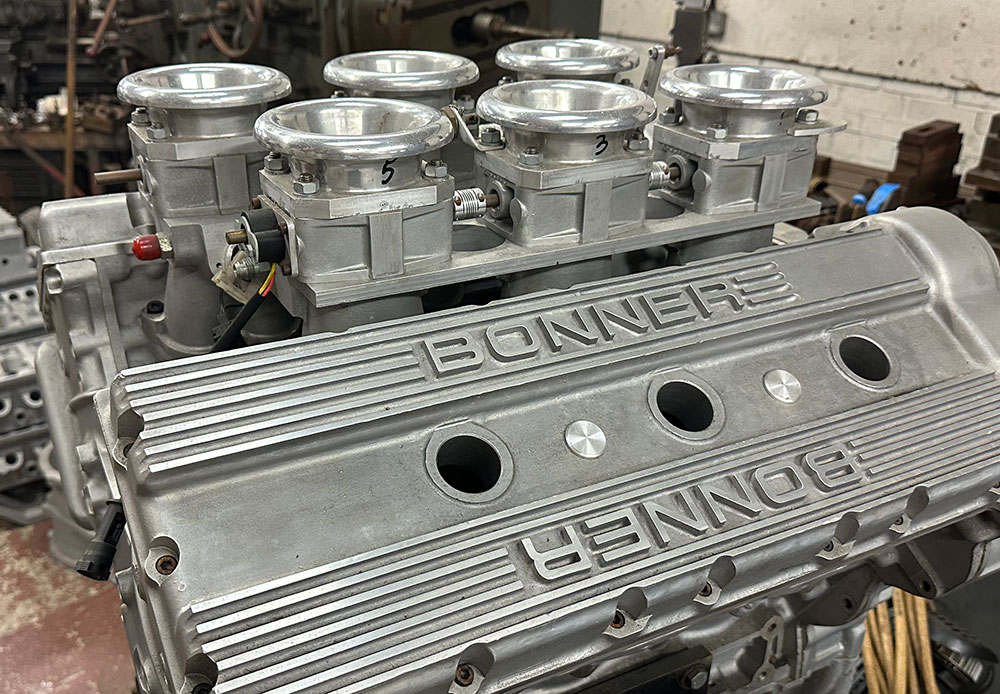

V6 Sports Car Engine

Question: But what about designing a cam profile or a crankshaft for an existing engine? What would be the point if you can buy the self same article out of a catalogue?

Answer: A crankshaft or camshaft out of a catalogue is generally good value for money, and for most people an answer to their requirement for a replacement without further thought. If an off-the-peg suit fits, the reason to have one tailor-made is to suit a special purpose, e.g. Raising the r.p.m. by 25% will not only raise the maximum power figure, but also widen the power band.

We had a highly esteemed client who wanted just that for his Lister powered by a Jaguar ‘D’Type Engine. When the engine arrived, we first fitted it to the dynamometer and tested it. Maximum power obtained was 295 bhp @ 5850 rpm. The red line was also 5850 rpm. So, on the track, at the precise moment of hitting peak power it would be necessary to change gear, and to a lower power level.

Next we dismantled and surveyed the engine, obtained a full set of dimensions, produced longitudinal and transverse sectional drawings, measured and plotted the cam profile on a graph, measured the valve springs: OD, ID, Wire Dia, No Coils Active, No Coils Total, Free Length, Fitted Length, Valve Open Length, Choc Length, and calculated Fitted Load, VO Load, Fitted Stress, VO Stress. From our knowledge of the cam profile, we could calculate, in addition to the lift and duration, the maximum positive acceleration, the maximum negative acceleration, so from the weight of all the components, we could calculate when valve bounce would occur. Actually, not a lot over 6000 rpm. Hence the red line @ 5850 rpm.

We then designed a spot-on camshaft, with increased lift but reduced negative acceleration, and a pair of special valve springs to match, and an exquisite fully calculated and counterbalanced crankshaft, and special Carillo con-rods which we designed, sent the drawings to Carillo in California, and they made them. All of this was to achieve a red line of 7,500 rpm, which we did successfully, and the engine gave a genuine 350bhp @ 6750 rpm with a useful power band from 4000 rpm to 7500 rpm. This is a unique engine, out there somewhere.